Marine Hose Specialists

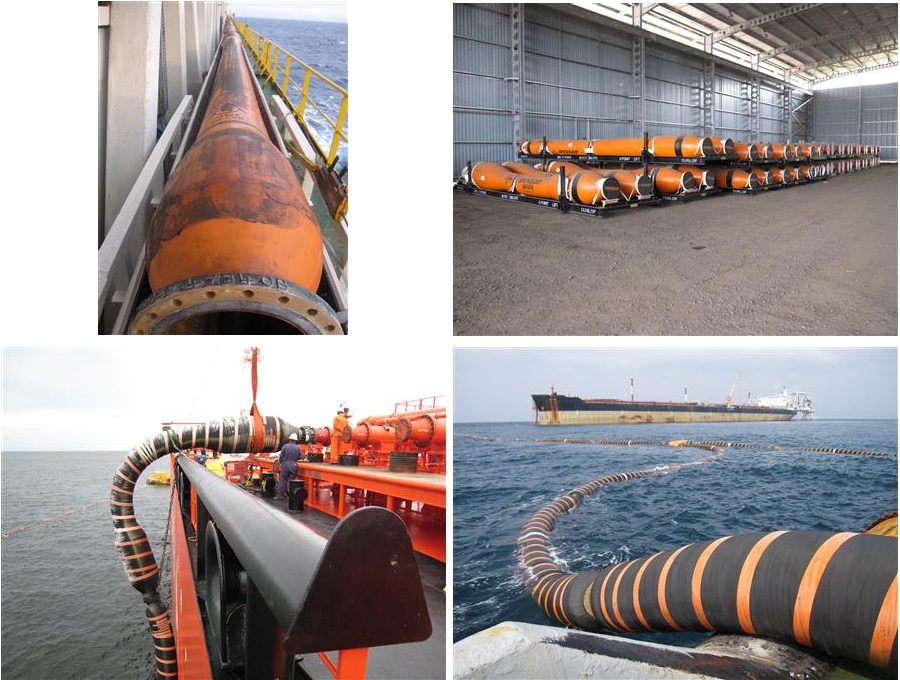

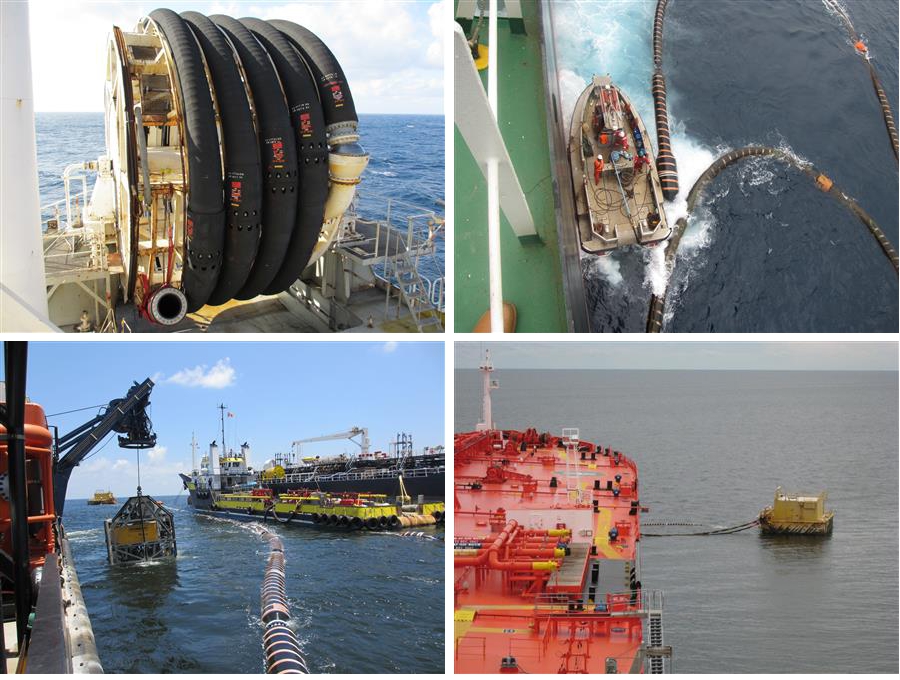

SERVICES PROVIDED IN THE FIELD

Our specialists are offshore certified and competent to support you at your terminal.

SERVICES PROVIDED REMOTELY

Our specialists are qualified engineers able to provide the following services around the world.

Integrity Management – Marine Hose Testing, Inspection, Repair, Refurbishment & Recertification

To maximise hose integrity we encourage Terminal Operators to have an annual survey by a Marine Hose Specialist and to periodically recertify their hoses onshore. Marine hose testing as part of a preventative maintenance plan helps minimise the risk of marine hose failure in service. In addition, retirement policies should be based on field performance verified by destructive testing.

During onshore re-certification the hoses can also be refurbished and repaired, as required. This forms part of our marine hose testing, inspection and re-certification service.

We perform the close inspections required to identify early signs of hose deterioration and issue third party site certificates subject to OCIMF marine hose tests being passed.

We can then build and maintain a hose database to help you manage marine hose integrity over the life of your terminal. All of the marine hose test data and service history is then available to access whenever required and can be used to plan end of life replacement.

Service Life Estimation

We offer inner liner rubber material testing to verify the aging rates while in service at your terminal. This would complement any burst test data you obtain at site and help corroborate other residual service life estimates.

To further optimise asset life we can recommend improvements to long term storage, handling, refurbishment and repair.

We will provide an impartial service life estimate, independent of the manufacturer and not influenced by the incentive of future marine hose demand.

Field Engineering Advice

We provide experienced field engineering personnel with expert knowledge of marine hose systems and their operation and maintenance and provide guidance for:-

• Storage

• Onshore Handling

• Assembly

• Towing

• Hook-up / Installation

• Commissioning

• Offshore Handling

• Flushing

• Inspection

• Testing

• Refurbishment

• Repair

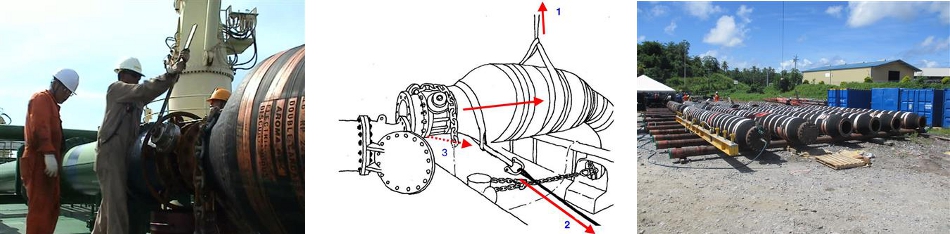

Our Marine Hose Specialists are fully trained in mechanical joint integrity and are available to support you in the field to:-

• Review procedures, suggest methods, tools and equipment suited to this task.

• Provide advice related to flush volume, pressure, flowrate, dispersant dosing and sampling to ensure the product is safely pushed out before breaking containment.

• Supervise to ensure hoses are handled correctly during assembly on a dock-side, slipway, beach or on the deck of a boat or barge.

• Supervise bolted flange integrity e.g. check torque values/sequence, flange alignment, bolt material/coating, gasket type/condition, etc.

• Witness post-assembly leak and post-installation commissioning tests.

• Check subsea string configurations and sign off.

• Inspect, witness testing and perform repairs.

Annual Survey

Our annual surveys are tailored to Client’s requirements and may include:-

• Visual inspection of hoses and accessories in service (internal and external).

• Visual inspection of hoses and accessories in storage.

• Risk assess stock levels.

• Highlighting equipment damage observed.

• Highlighting gaps in operation and maintenance best practice.

• Trouble-shoot incidents.

• Discuss procedures and retirement policy.

• Witness ongoing hose recertification (routine inspection & testing).

• Witness burst testing and liner sample removal.

• Advise during hose changeout activities.

• Participate in risk assessments.

• Perform outer cover repairs.

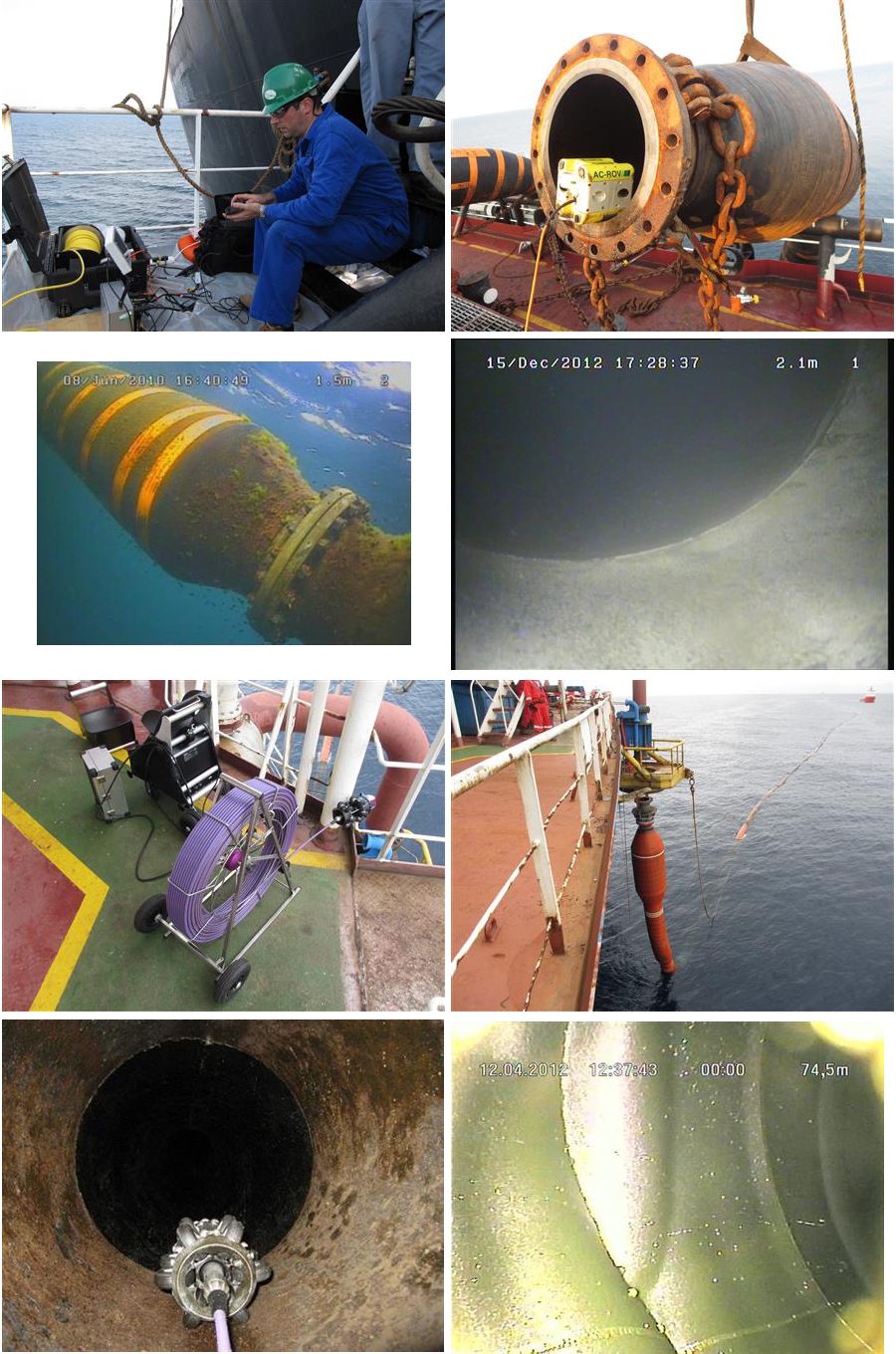

External and internal visual inspection by ROV and Push-Rod Camera

We perform in-situ visual inspections by ROV and push-rod camera of the bore of the hoses after the strings have been suitably seawater flushed or Nitrogen purged.

Our ROV and Push-Rod visual inspection services enable you to:-

• Monitor the INTERNAL condition of floating, reel, chute and catenary hoses.

• Monitor the INTERNAL condition for signs of nipple corrosion, liner damage and carcass kinking.

• Monitor the EXTERNAL condition in seas of up to 1m swell and 1 knot current.

• Identify damage/deterioration anomalies before failure.

• Reduce unexpected failure by periodically inspecting OCIMF marine hoses in-situ.

• Reduce health and safety risks by reducing visual inspections by diver.

• Reduce periodic inspection cost compared to hose string breakdown for deck/onshore inspection.

We look for:

• Liner damage

• Nipple corrosion

• Kinking

• Impact damage

• Abrasion

• Buoyancy configuration

• Bead float security or damage

• Leak detection system activation

• Loose bolts

• Early signs of deterioration

• Excessive marine growth

Reasons why:

• Business Continuity: Reduce unexpected failures/loss/maintenance.

• Reduced H&S Risk: Avoid unnecessary hose string breakdown.

• Reduced Time: Hose string inspection within hours.

• Reduced Cost: Cheaper than onshore recertification or disaster recovery.

• Rapid Response: Possible to take ROV as checked-in luggage.

• Increase Scope of Inspection: Include areas traditional inspection methods can’t reach.

• Technical knowledge: Of all well-known marine hose brands.

• Records: Periodic condition monitoring with video & photographic records.

Incident Investigations - Root Cause of Failure Analysis

In the event of a hose incident or failure, we have a great deal of experience and know-how to quickly find the root cause of failure and to help you take steps to avoid the same failure mode re-occurring.

Typical counter-measures include:-

• Hose design modification

• System design modification

• Handling procedure modification

• Training

Operations & Maintenance Training

We are committed to continuous development and knowledge sharing. There are many challenges within our industry which we can all help tackle by sharing our experiences, to help improve the offshore industry and best practices.

With our experience, we are well placed to give impartial, expert advice on a wide range of topics throughout the hose’s life from system feasibility stage to hose disposal.

We have built a global reputation on our substantial technical expertise, our insistence on high standards and the exceptional care we take on all projects. With an abundance of knowledge at our fingertips, we can tailor our training to your specific requirements, giving attendees a broader understanding of the subject area, utilising lessons learnt, new developments and the latest in inspection technology.

Our Marine Hose Specialists provide bespoke training on-site or at our offices. Typical topics include:

• Offshore in-service test and inspection guidelines including common failure modes and what to look for during visual inspections.

• Offshore installation, operation and handling guidelines.

• Onshore storage, handling & assembly guidelines.

• Onshore recertification (periodic test & inspection) guidelines including common failure modes and what to look for.

• Service life estimation and extension risk assessment.

• Sparing recommendations.

• Repair guidelines.

• New inspection techniques.

• Ancillary equipment guidelines.

• OCIMF guidelines.

• Manufacturer’s recommendations.

Purchase Specification Review

We recommend your marine hose specification be reviewed. Since start-up several lessons will have been learned and as a result, modifications can be made to the hose designs for your terminal. It would be constructive for these modifications to be captured in your purchase specification, to avoid repeat incidents and to improve overall hose system performance.

The new edition of the “OCIMF Hose Guide” is now available. GMPHOM 2009 contains many changes designed to improve the durability and reliability of the marine hoses produced. We can guide you through the transition to ensure compatibility between your “old” OCIMF 1991 hoses and hoses manufactured in accordance with the new guidelines.

Our Scope:

• Prepare the Specification to suit your terminals needs.

• Assist Technical Evaluation to ensure compliance with GMPHOM 2009.

• Witness Critical Tests to ensure fitness of purpose.

System Design Verification

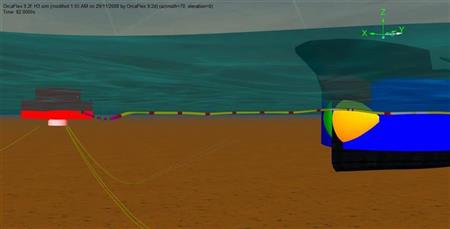

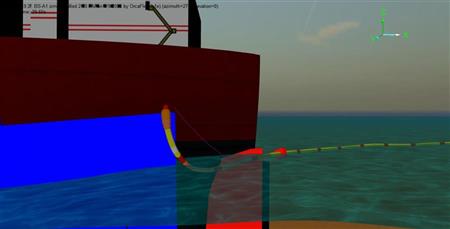

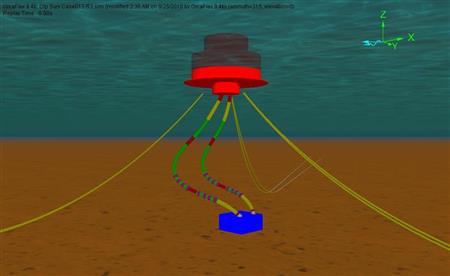

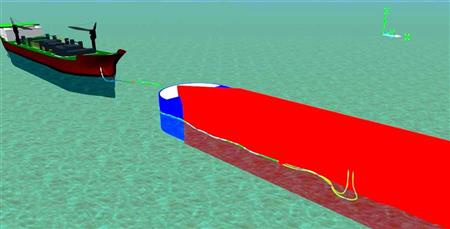

Using our ORCAFLEX finite element software licence we are able to perform system design verification checks to confirm whether:-

• The marine hoses originally supplied are suitable for the buoy system.

• Evaluate and justify any system design and/or hose design changes.

• To troubleshoot configuration problems and justify solutions.

Evaluating Alternative Suppliers - Brand Mixing Compatibility Studies

Using our ORCAFLEX finite element software licence we are able to perform compatibility studies which enable the end user to mix brands with confidence as we identify where brand mixing is acceptable and where it should be avoided.

• Brand mixing is technically undesirable.

• Single source is commercially unacceptable.

• We enable the end user to mix brands with confidence.

• We identify where brand mixing is acceptable and where it should be avoided.

• We highlight where brand mixing may adversely affect hose service life.

• Original Equipment supplier & ……… alternatives nominated by you. Your choice.

Once compatible suppliers are short-listed we can assist with technical bid evaluation and be your representative during factory acceptance tests.

We also verify that the technical specifications and prototype approval of alternative manufacturers meet requirements of the up-to-date OCIMF guidelines (GMPHOM 2009) and your terminal’s unique needs.

Service Life Extension Risk Assessment

Should you wish to extend the service life of your marine hoses in service, we can perform a detailed risk assessment to highlight the potential risks associated with the proposed life extension.

We risk assess service life extension as follows:-

• Identify failure modes & develop them into a set of representative risk scenarios.

• Identify root causes, current risk control measures and suggest additional controls.

• Examine the consequences of each scenario.

• Estimate the probability of each failure mode.

• Highlight the potential risks associated with the proposed life extension.

• Identify and assess any risk reduction measures and discuss practicalities.

• Recommend whether to extend the service life or not.

Recommendations, Manuals, Procedures and Step-by-Step Visual Guides

We have produced visual guides to complement OCIMF guidelines and Manufacturers’ Manuals to assist the operator. Example guides include:-

• Offshore Inspection Guidelines

• Offshore Hose Handling & Connection Step-by-Step Guide

• Onshore Recertification Guidelines

• Destructive Test Manual (for service life estimation)

• Hose Changeout Overview Procedure

• Refurbishment and Repair Manuals

• Sparing Recommendations

• Storing Recommendations

Marine Hose Disposal

Once the marine hoses have reached a point at which it is not advisable to continue using them for transferring crude oil and/or refined products, they can either be:-

• Cleaned and reused in a non-hydrocarbon application or

• Put beyond use and disposed of in a safe and environmentally responsible manner in accordance with local regulations.

Please confirm the quantity, size, type, condition and location of your retired marine hoses and we will propose a solution.